A Matter of Choice: 4 Steps to Select Material and Grade

Material properties serve as a convenient screen to narrow options for the designer or engineer. Final grade selection is application specific and usually involves a compromise between part design, secondary performance features, handling and aesthetics. The following steps can be considered in narrowing down which material type and grade fits a specific application.

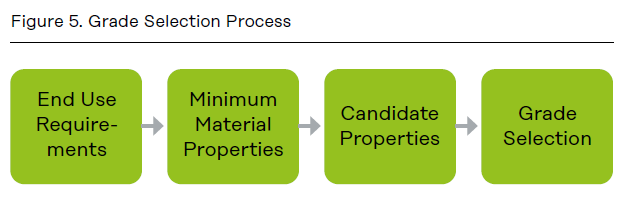

Four steps for selecting material type and grade:

1. Define the end use performance requirements

2. Translate performance requirements into minimum

material properties

3. Screen for candidate materials that meet minimum

properties

4. Select the best grade from the candidate materials list

Commercial considerations such as cost and availability are also important factors in the decision, as are agency approvals, regulatory compliance and OEM (original equipment manufacturer) specifications, if applicable. Manual screening using data sheets and information obtained directly from suppliers is practical when considering a limited number of materials. Data sheets for all commercial grades of Bakelite® Molding Compounds can be obtained directly from the Bakelite Synthetics website.

When evaluating a wide range of materials or comparing dissimilar types, such as engineering thermoplastics (ETP), engineering thermosets (ETS) and metals, manual screening is cumbersome but electronic material databases are an excellent resource. Search functions enable rapid screening by key properties and user created data tables allow side-by-side comparisons of multiple grades. CAMPUS, MatWeb, and UL Prospector are three major global materials databases that contain data for engineering thermoplastics and engineering thermosets including all commercial grades of Bakelite® Molding Compounds. MatWeb & UL Prospector also contain metals data.

Electronic databases also contain multipoint data typically not included in standard product data sheets. Stress-strain curves at elevated temperatures, modulus vs. temperature and creep elongation over time under different conditions are examples of the kind of multipoint data that are available for many materials, including certain Bakelite® Molding Compound grades. These data can often be imported directly into computer-aided design software.