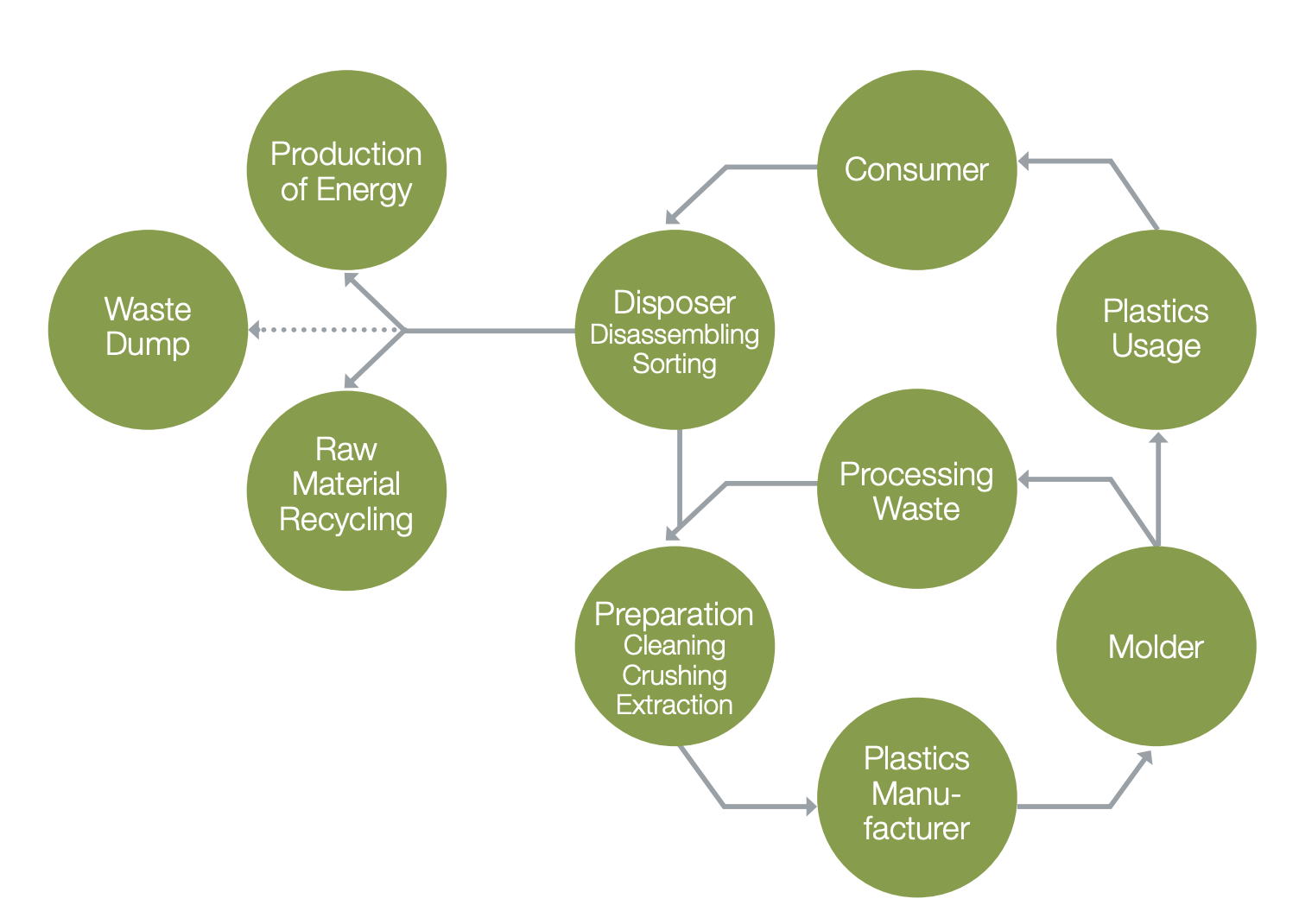

Sustainability Matters: 3 Ways to recycle Engineering Thermosets

It is possible to recycle engineering thermosets in several ways: mechanical, chemical, or as a filler in making cement. Mechanical recycling involves grinding cured thermoset scrap and reintroducing it as a filler in fresh molding compounds. Chemical recycling involves pyrolysis or solvolysis whereby the matrix material is separated from the fiber reinforcement and is digested to basic components that can be reused. A third approach, promoted in Europe and Japan, involves the use of thermoset scrap in the cement making process.

Inorganic components are reduced to ash and bond with the cement clinker, while the organic component serves as a thermal energy source in the calcination process. Finally, incineration is considered a suitable method for disposing of thermoset waste, extracting thermal energy from the organic component.

Thermoset parts may have lower environmental impact – eg. GWP (global warming potential) – than aluminum over the lifecycle. This was shown in a case study, comparative peer-reviewed LCA (life cycle analysis) of a water pump housing made of injection molded phenolic engineering thermoset vs. die cast aluminum (Heide S. t., SPE ACCE presentation 2015.)

Our downloadable info-sheet diagrams a typical life-cycle for thermoset automotive under-the-hood parts.